Parsa Polymer Sharif’s UV Masterbatches

06 May 2025

Plastic products are highly susceptible to degradation due to prolonged exposure to harmful environmental factors, especially ultraviolet (UV) radiation. Signs of this degradation include brittleness, discoloration, and the loss of physical properties such as impact strength, tensile strength, and fading—all of which significantly reduce the lifespan of plastics. To maintain the durability and integrity of plastics, the use of UV stabilizers is essential. This article examines the various types of UV stabilizers and their mechanisms of action.

Polymer Degradation Caused by UV Radiation

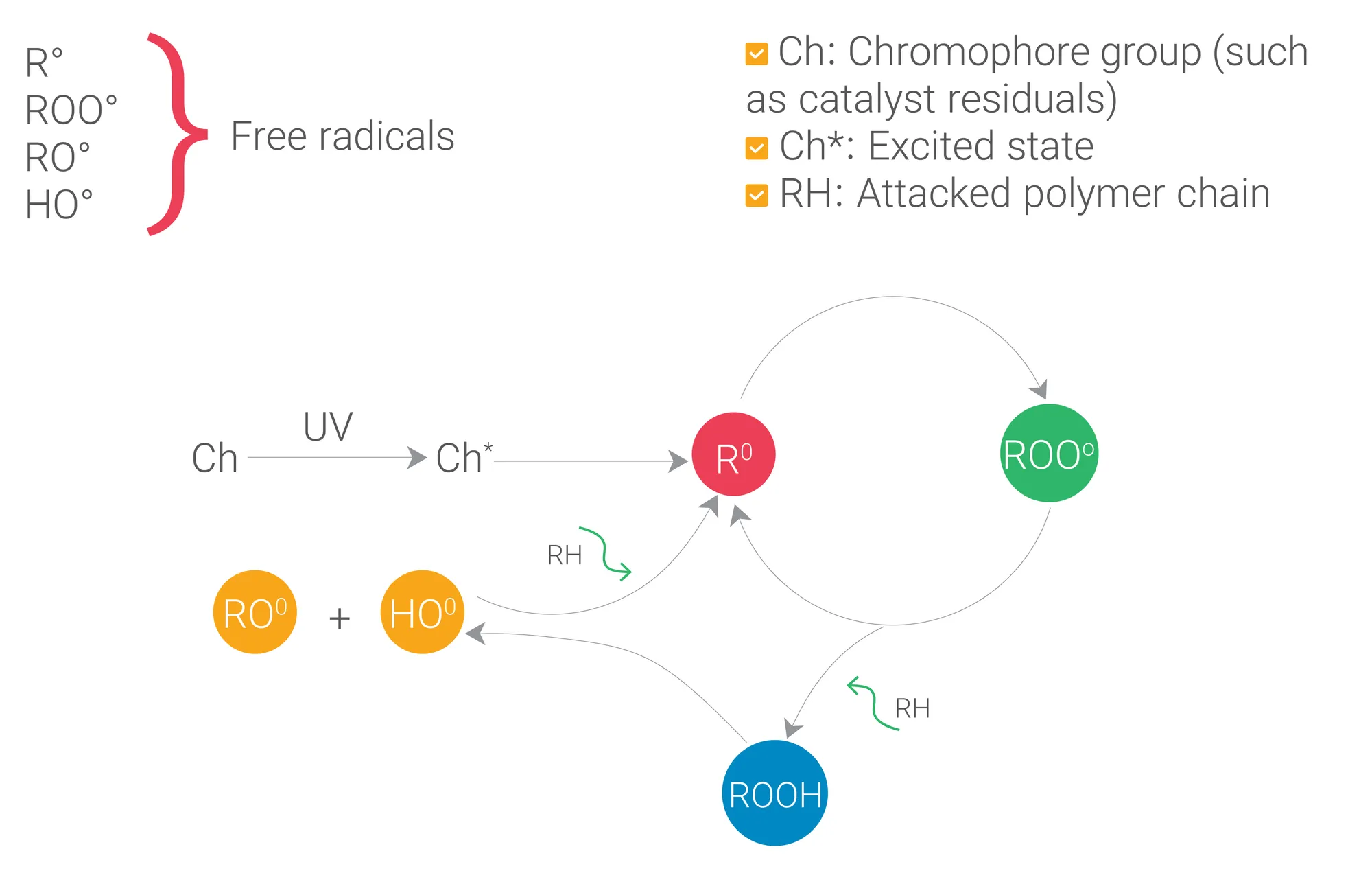

Ultraviolet (UV) radiation is a type of electromagnetic radiation with wavelengths between 290 and 400 nanometers, accounting for about 10% of the sun’s electromagnetic output. As shown in Figure 1, when polymers are exposed to UV radiation, chromophores within the polymer absorb the radiation and generate free radicals, triggering chain reactions. Over time, this leads to the breaking down of polymer chains and material degradation.

Common signs of UV degradation include:

- Discoloration

- Surface cracking

- Decreased tensile and impact strength

- Surface chalking

UV-induced degradation is a major concern for products like automotive parts, outdoor furniture, agricultural films, and building materials that are frequently exposed to sunlight.

Figure 1 – Photodegradation Process of Polymers.

UV Stabilizers in Plastics

UV stabilizers are additives used to mitigate the harmful effects of UV radiation and extend the lifespan of plastic products. These additives are typically incorporated into polymers during manufacturing, often in the form of masterbatches. Key reasons for using UV stabilizers include:

- Prolonging product lifespan

- Preserving product appearance

- Maintaining mechanical properties

- Reducing waste and associated economic costs

Types of UV Stabilizers in Plastics

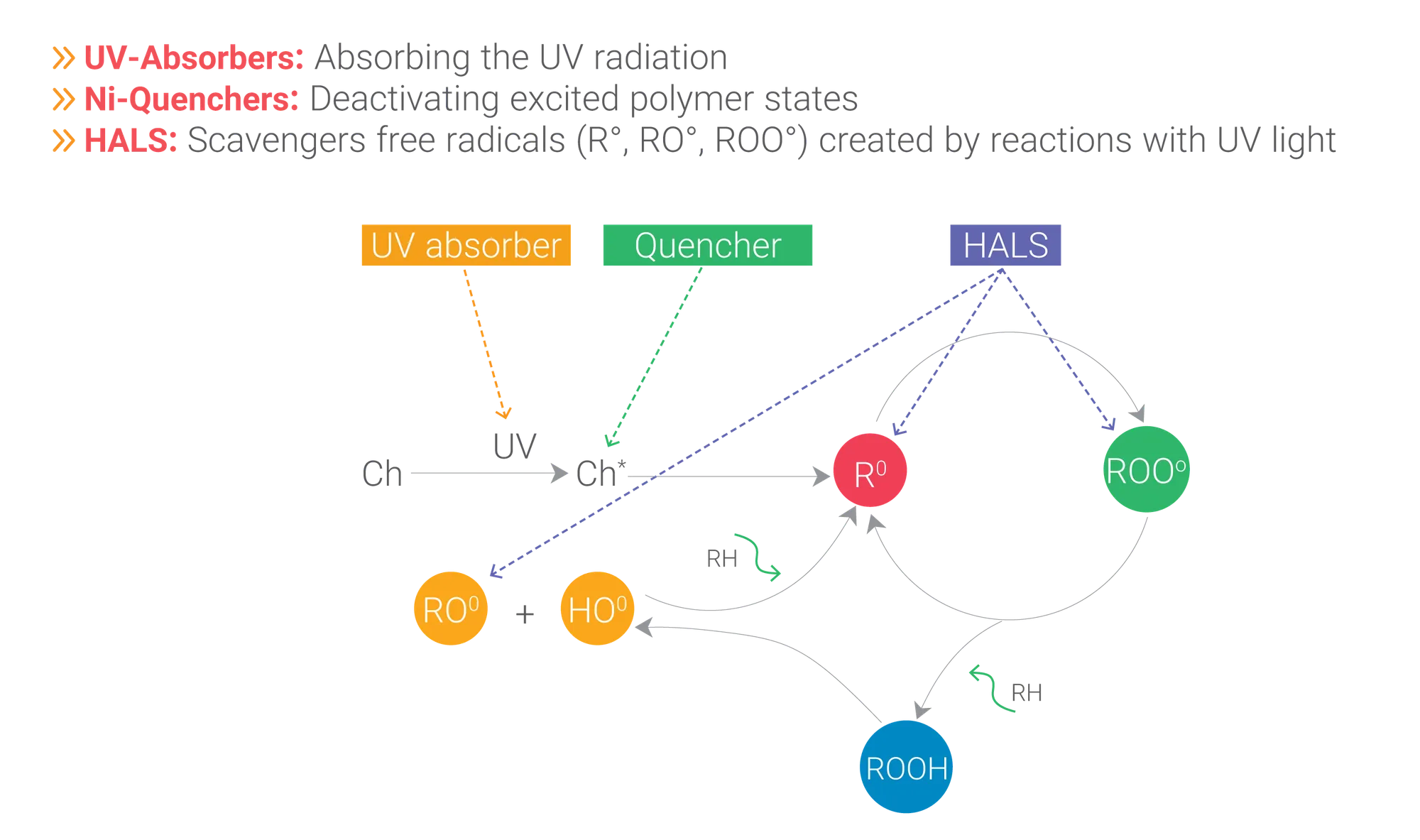

There are several types of UV stabilizers, each with different mechanisms of action and applications. The most commonly used UV stabilizers in polymers include UV absorbers (UVA), quenchers, and hindered amine light stabilizers (HALS). Their functionalities are briefly illustrated in Figure 2.

Figure 2 – Mechanisms of UV Stabilizers.

UV Absorbers (UVA)

UV absorbers are among the most widely used UV stabilizers in the plastics industry. They protect polymers by absorbing harmful UV radiation and converting it into harmless infrared radiation or heat, thus preventing the radiation from reaching and degrading the polymer chains. They are particularly effective for products exposed to short-term UV exposure but are less efficient for long-term applications.

Common UV absorbers include:

• Carbon Black: Highly effective due to its strong UV absorption and characteristic black color.

• Rutile Titanium Dioxide: Highly efficient in the 300–400 nm wavelength range but less effective below 315 nm.

• Hydroxybenzophenone: Commonly used for general-purpose UV protection.

• Oxanilides: Particularly useful for providing long-term stability.

• Hydroxyphenyl Benzotriazoles: Not suitable for thin parts (<100 microns), but excellent for UV absorption in specific applications.

• Benzophenones: Effective across the 200–380 nm range and widely used in clear polymer applications like optical lenses, coatings, and films where transparency and color stability are crucial.

• Benzotriazoles: Provide strong protection within the 300–400 nm range, suitable for automotive coatings, packaging, and construction products.

• Hydroxyphenyl Triazines: Ideal for harsh environments due to their high thermal stability and resistance to migration, making them suitable for automotive parts and outdoor furniture.

Each absorber is effective within specific wavelength ranges and is selected based on the type of polymer and its intended application. For optimal UV protection, UV absorbers are often combined with other stabilizers, such as HALS, to achieve a synergistic effect and improved performance.

Quenchers

Quenchers are a type of UV stabilizer, sometimes referred to as light stabilizers. They work by deactivating the excited molecules generated by UV radiation absorption, converting the absorbed energy into harmless heat and preventing polymer chain degradation. Nickel-based quenchers are a known example and are effective in converting excited energy into heat.

However, quenchers are generally considered less effective than UV absorbers or HALS in blocking UV radiation. Therefore, they are often used in combination with other stabilizers for better protection, especially in applications that do not require prolonged UV resistance.

Hindered Amine Light Stabilizers (HALS)

HALS are among the most effective additives for protecting polymers—particularly polyolefins—against photodegradation caused by UV-induced oxidation. Unlike UV absorbers, HALS do not absorb UV light; instead, they trap and neutralize free radicals formed during the degradation process.

These stabilizers typically feature a 2,2,6,6-tetramethylpiperidine structure, which plays a crucial role in their functionality. Even small amounts of HALS can significantly improve polymer stability thanks to their regenerative mechanism, which minimizes additive consumption during protection.

HALS are highly effective for applications involving wide surface areas, such as films and fibers, where long-term UV exposure is expected.

Criteria for Selecting UV Stabilizers

The choice of UV stabilizers should be based on several key factors:

• Environment: Additives must be formulated according to the climatic and environmental conditions where the final product will be used.

• Final Product Properties: Stabilizers must match the physical and mechanical characteristics of the final product to ensure optimal performance.

• Part Thickness: The type of stabilizer should correspond to the part’s thickness, as thickness affects stabilizer efficiency.

• Color: Different pigments have a different level of sensitivity to UV light; stabilizers must be selected to align with the product's color properties.

• Product Life cycle: The expected lifespan of the product (short-term vs long-term exposure) dictates the appropriate type of UV stabilizer.

Parsa Polymer Sharif offers UV stabilizer masterbatches under the brand name ParsaAdd. These masterbatches contain advanced combinations of absorbers and amine-based additives to enhance the durability and lifespan of plastics according to the highest global standards.

Collaborations with leading international companies in polymer additives have ensured that these products offer superior effectiveness compared to similar materials.

Applications of these masterbatches include artificial turf, urban furniture, agricultural films, durable packaging (e.g., woven sacks and jumbo bags), automotive parts, and generally any polymer component intended for prolonged outdoor exposure.

References:

1. https://europlas.com.vn/en-US/blog-1/uv-stabilizers-in-plastic-4-common-types-and-applications

2. https://plasticsrubber.basf.com/global/en/plastic_additives/products/light-stabilizers

3. https://eupegypt.com/blog/all-types-of-uv-stabilizer-for-polymers-you-should-know/

4. https://amcorplastics.com/additives-for-uv-stabilization/

5. https://www.songwon.com/products/polymer-stabilizers