Flame Retardant Plastic Compounds

10 November 2024

Introduction

Plastics are widely used in various industries due to their light weight, durability, and versatility. However, most plastics are highly flammable and can pose significant hazards. Only a few polymers, such as polyetherimide (PEI), are inherently heat resistant and fall into the category of non-flammable or self-extinguishing plastics. Flame retardants are chemical compounds that enhance the flame resistance of plastics, playing an essential role in reducing fire hazards and improving safety. Flame retardants can be chemically bonded to the polymer molecule or added as an additive during processing. With increasing safety requirements, especially in electrical and electronics, construction, household appliances, and public transportation, flame resistant plastics have gained importance. In this article, various types of flame retardants, their mechanisms of actions, and the standards of flammability will be discussed.

Types of Flame Retardants

A wide range of flame retardants with various structures and chemical properties are available for use in plastics. Common types include:

Halogenated Flame Retardants

These are among the first flame retardants used in plastics, containing halogen elements like bromine, chlorine, or both. They offer effective flame resistance at low concentrations, retaining mechanical properties, good processability, and cost-efficiency. However, due to environmental toxicity concerns, including their persistence in ecosystems, their use has been restricted in recent years in many countries.

Phosphorus-Based Flame Retardants

Covering a broad spectrum of phosphorus compounds with various oxidation states, phosphorus-based flame retardants provide high safety and are environmentally friendly, though they generally have lower effectiveness compared to halogenated options.

Nitrogen-Based Flame Retardants

These include melamine and melamine derivatives and are often used in conjunction with phosphorus-based retardants. They have a growing market share and offer advantages such as low toxicity, low smoke, minimal corrosion, and environmental compatibility.

Metal Hydroxide Flame Retardants

Commonly used metal hydroxides, such as aluminum trihydroxide and magnesium dihydroxide, are non-halogen flame retardants that meet standards for various applications. They are relatively non-toxic, produce low smoke, and are increasingly used as substitutes for halogenated retardants.

Sustainable and Eco-Friendly Flame Retardants

Made from green or biodegradable chemicals, sustainable flame retardants aim to minimize environmental impact, particularly for halogenated types. These retardants offer better recyclability and may be biodegradable.

Mechanisms of Flame Retardant Action

To understand how flame retardant materials work, it is important to know how plastics burn. Plastics burn through a process called pyrolysis, where polymer chains break down into smaller hydrocarbon molecules and flammable gases under heat. These gases mix with oxygen, producing free radicals such as hydrogen (H) and hydroxide (OH). Flame retardants interrupt these processes through various mechanisms:

Vapor Phase Inhibition

In this mechanism, flame retardant additives react with the burning polymer in the vapor phase, disrupting the production of free radicals at the molecular level, effectively stopping the combustion process. This is typically seen in halogenated flame retardants containing bromine and chlorine.

Char Formation in the Solid Phase

Some flame retardant additives create a thick, solid carbon (char) layer on the polymer surface. This layer insulates the polymer, preventing reactive gases from escaping, which halts the combustion process. This mechanism is commonly activated in non-halogenated systems based on phosphorus and nitrogen.

Quenching and Cooling

Flame retardants utilize an endothermic reaction in the presence of fire to release water molecules, cooling the polymer and delaying combustion. This mechanism is typically active in non-halogenated flame retardants containing metal hydroxides.

Flammability Standards for Plastics

Various tests and standards, such as UL94 and Glow Wire, have been established to evaluate the flammability of plastics, each examining specific flammability properties.

UL94 Test Criteria and Classifications

UL94 is the most common flammability test for plastics, published by Underwriters Laboratories (UL), which categorizes plastics based on their burning behavior in different orientations.

Horizontal Burning Test (HB)

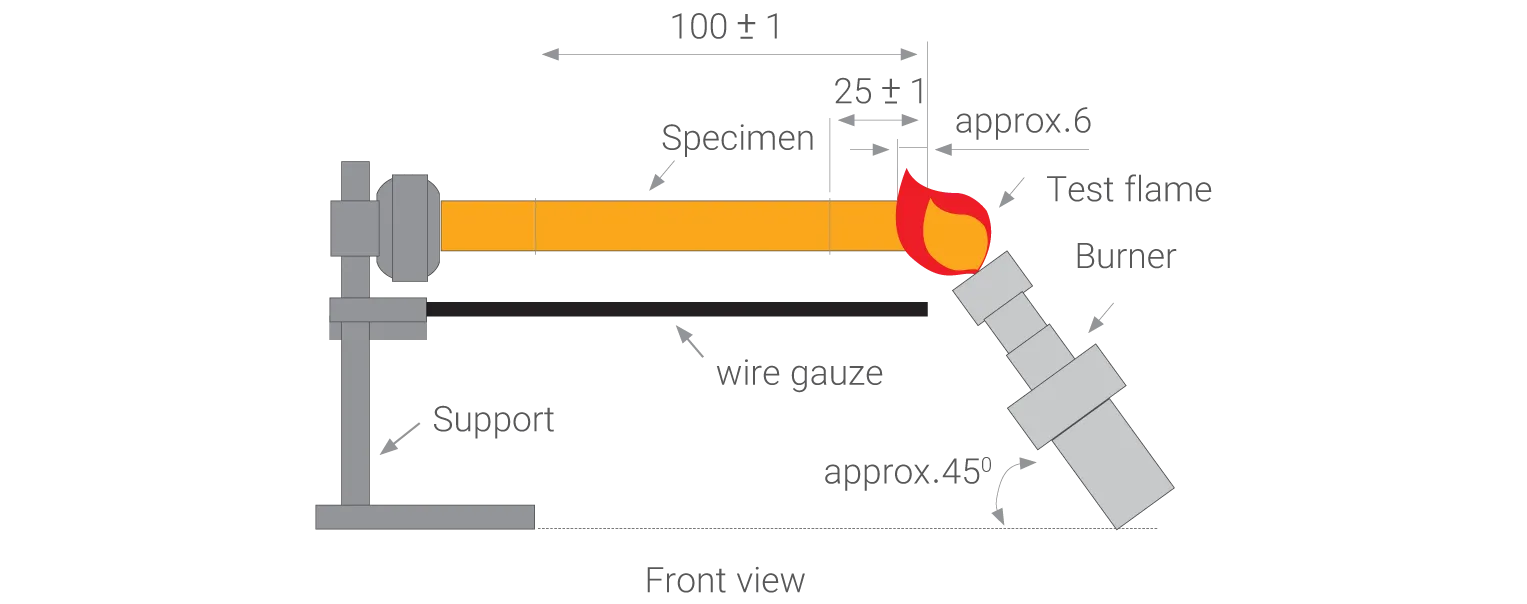

In this test, the material's burning rate is measured to determine flame spread in a horizontal orientation. As shown in Figure 1, the sample is positioned horizontally and exposed to a direct flame for 30 seconds before the flame is removed. Samples less than 3 mm thick must burn at a rate of less than 76 mm/min to qualify as UL94 HB.

Figure 1- Schematic of UL94 Horizontal Burning Test.

Vertical Burning Test (V)

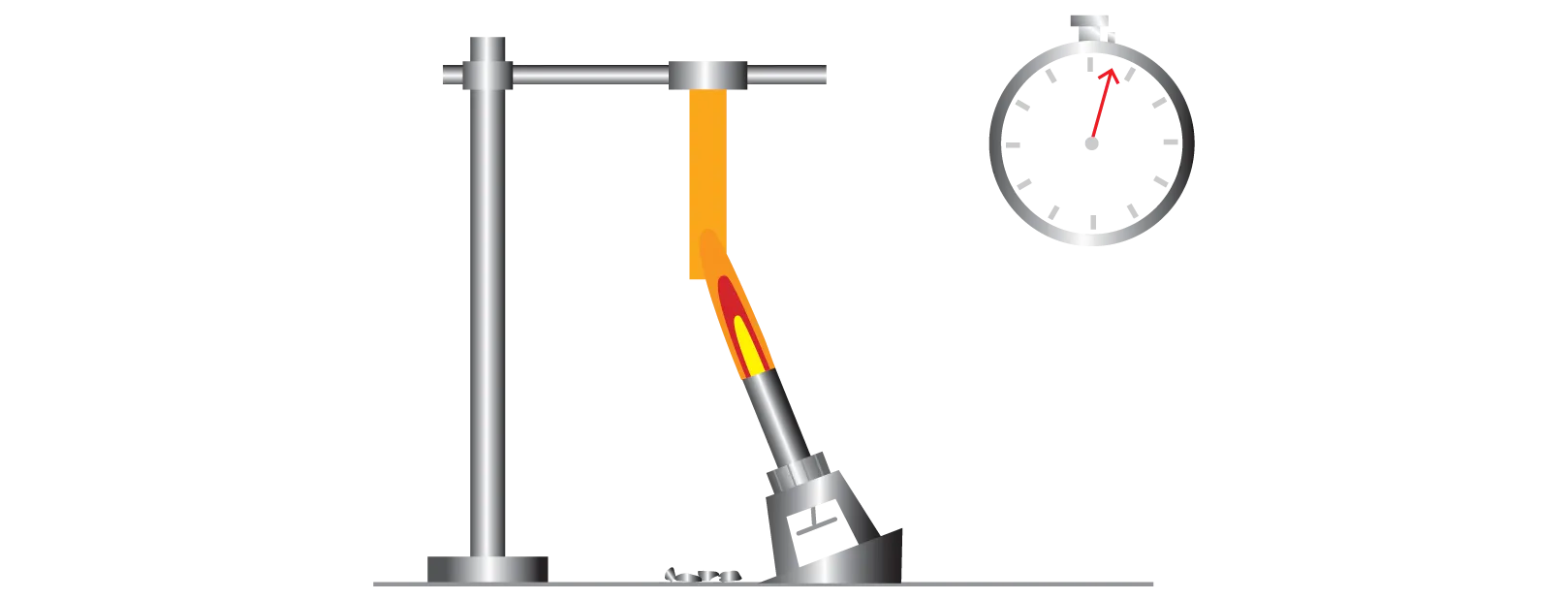

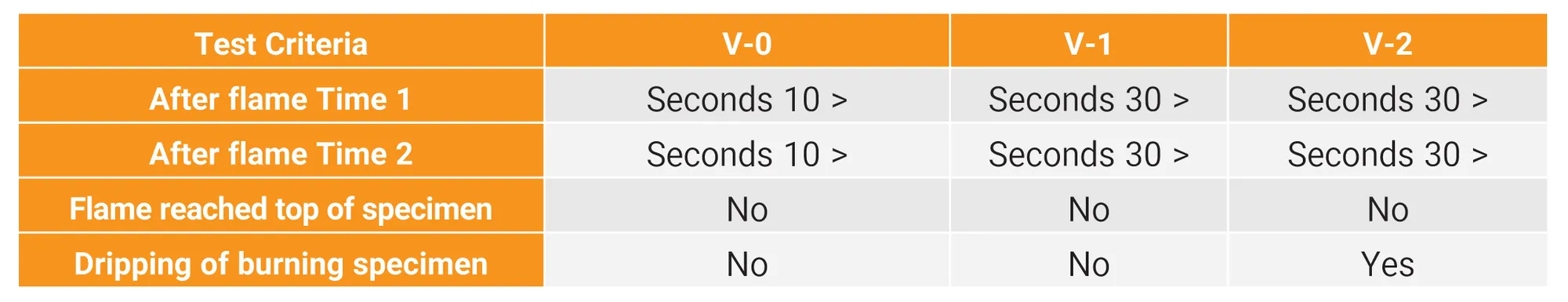

In this test (Figure 2), the sample is positioned vertically and ignited. Burning time and dripping behavior are observed. Results are classified as V0, V1, and V2, with V0 indicating the highest flame resistance and V2 the lowest, as summarized in Table 1.

Figure 2- Schematic of UL94 Vertical Burning Test.

Table 1- Vertical UL Classifications

Glow Wire Test

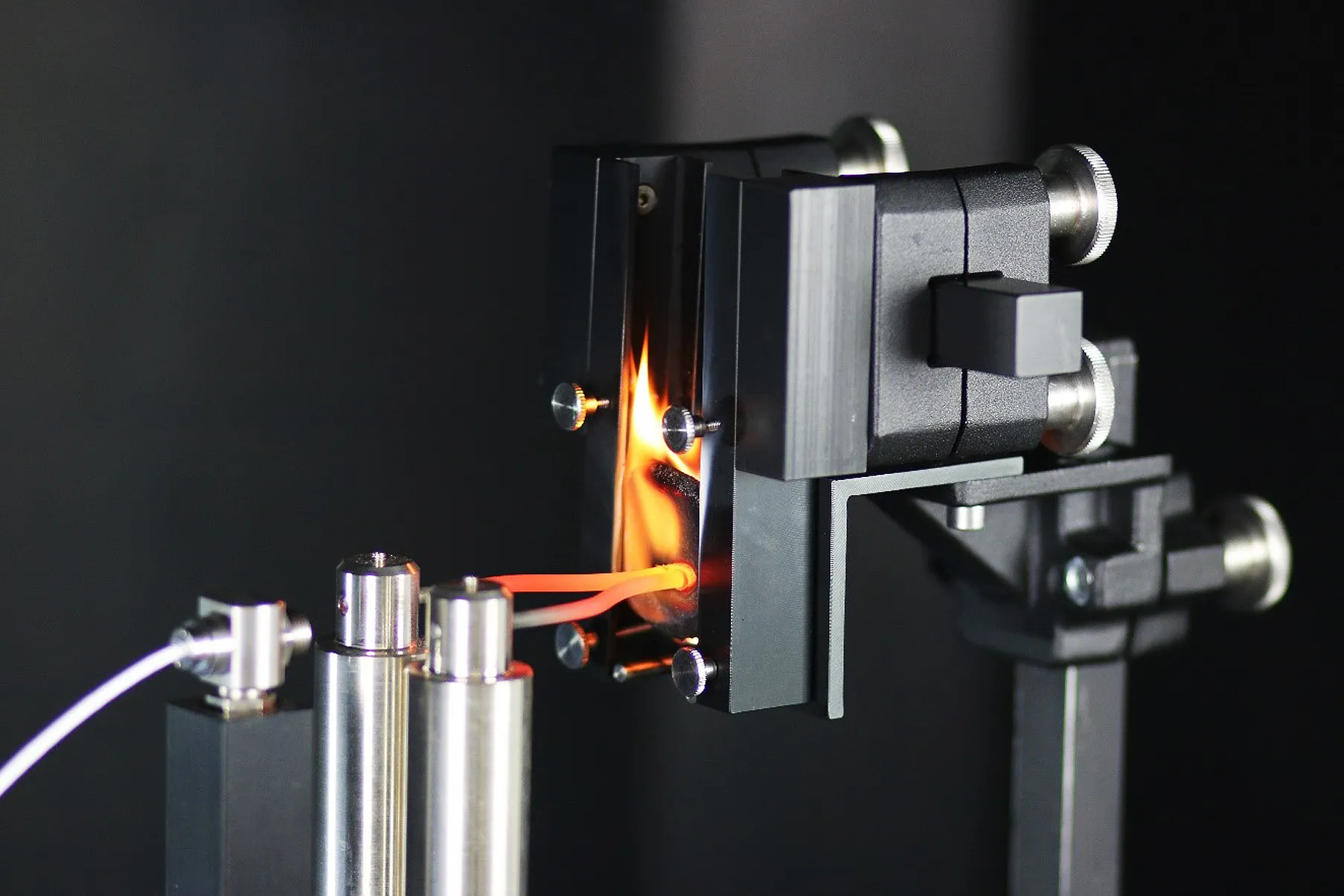

The flammability of plastics is also measured by the Glow Wire Test according to IEC 60695-2-10, typically reported as the Glow Wire Flammability Index (GWFI). In this test (Figure 3), a wire is heated to a preset temperature (650–960 °C) and contacts the sample for a defined time and force. The highest temperature at which the material does not ignite or self-extinguishes within 30 seconds is recorded as GWFI.

Figure 3- Glow Wire Test setup.

Parsa Polymer Sharif Flame Retardant Compounds

Parsa Polymer Sharif is a leading manufacturer of flame retardant compounds for applications across various industries, including electrical and electronics, household appliances, and automotive. The company's flame retardant compounds are based on resins such as polypropylene (PP), polyamide (PA), acrylonitrile butadiene styrene (ABS), polybutylene terephthalate (PBT), and engineering alloys, utilizing both halogenated and non-halogenated flame retardants. These compounds meet UL94 V-0, V-1, V-2, and Glow Wire standards and offer excellent processability and durability.

References:

1. https://polymer-additives.specialchem.com/selection-guide/flame-retardants

2. https://www.rtpcompany.com/products/flame-retardant/

3. https://www.plasticdesigninc.com/blog/flame-retardant-plasitc-materials/