Polyamide Compounds (PA) in Various Industries: Innovative Solutions for Industrial Applications

12 October 2024

Polyamide, commonly known as nylon, is one of the most widely used and important engineering thermoplastics. Due to its unique balance between technical performance and cost, it has become a viable alternative to metals in many industries, particularly for manufacturing lightweight and durable parts. Polyamide compounds are available in various types, including Polyamide 6 (PA6), Polyamide 66 (PA66), as well as specialized grades such as Polyamide 46 (PA46). These numbers refer to the molecular structure of the polyamide, which determines its physical and chemical properties. Each type possesses unique characteristics suited for specific applications. The most commonly used polyamide types in industry are PA 6 and PA 66.

Key Features of Polyamide

Polyamide holds a special place among engineering plastics due to its unique properties, including:

High strength and durability at elevated temperatures: Polyamide maintains mechanical strength even at high temperatures, making it ideal for automotive and engineering components exposed to heat.

Excellent impact resistance, even at low temperatures: This property makes polyamide suitable for applications requiring energy absorption and fracture prevention under harsh conditions.

Low viscosity and easy processability: Due to its low viscosity, polyamide is easily processed in plastic manufacturing techniques like injection molding and extrusion.

Exceptional chemical resistance to oils and greases: This is particularly important in industries like automotive and machinery where components are in contact with chemicals.

High fatigue resistance: Polyamide parts have a longer service life due to their high resistance to repeated stress and deformation.

Good electrical insulation: Polyamide is widely used in electrical and electronic applications such as sockets and terminal blocks due to its insulating properties.

Lightweight and low density: Reducing the overall product weight without sacrificing strength is a major advantage, especially in the transportation and automotive industries.

Limitations of Polyamide

Despite its numerous advantages, polyamide has some limitations that must be considered for specific applications:

High moisture absorption: Polyamides tend to absorb moisture from the environment, which can affect their mechanical properties and dimensional stability.

Poor dimensional stability: Due to moisture absorption, polyamide parts may experience dimensional changes, which can be undesirable in precision applications.

High processing temperatures: Polyamide requires high processing temperatures, which can increase energy costs.

Low resistance to strong acids and bases: While polyamide exhibits good chemical resistance to oils, it presents limited resistance to strong acids and bases. Exposure to these environments can lead to chemical degradation or loss of mechanical properties.

Flammability: Polyamide is naturally flammable, so flame retardants need to be added for specific applications.

Higher cost compared to standard plastics: Polyamide is relatively more expensive than some other plastics, especially general-purpose ones.

Diverse Applications of Polyamide

Polyamide compounds, known for their durability and high strength, are used in various industries, including but not limited to:

Textile Industry: Polyamide is widely used in the production of textiles like carpets, sportswear, and durable clothing.

Automotive Industry: Due to its thermal and mechanical properties, polyamide compounds are used in the production of cooling fans, air intake manifolds, engine components, and door handles.

Electrical and Electronic Components: Polyamide is used for producing components such as sockets, plugs, switches, and terminal blocks because of its insulation properties and heat resistance.

Kitchenware: Polyamide’s heat resistance makes it suitable for manufacturing kitchen utensils like spatulas and ladles.

Industrial Parts: Polyamide is used for making components such as bearings and gears that require wear resistance.

Packaging: Films made from polyamide are widely used in food and pharmaceutical packaging due to their barrier properties.

Types of Polyamide Compounds and Their Applications

Polyamides can be modified with various additives such as fillers, reinforcing fibers, and impact modifiers to enhance their mechanical, thermal, and chemical properties. Common types of polyamide compounds include:

Fiber reinforced polyamide compounds: Adding glass, carbon, or aramid fibers significantly enhances the strength and stiffness of polyamide. These compounds are ideal for producing industrial components such as gears and bearings that require high strength and wear resistance.

Mineral filled polyamide compounds: The addition of mineral fillers like talc and calcium carbonate improves the stiffness, dimensional stability, and heat deflection temperature of polyamide. These compounds are commonly used in automotive and engineering applications.

Flame-retardant polyamide compounds: The addition of flame retardants reduces the flammability of polyamide, making these compounds suitable for applications such as electrical components.

Impact-modified polyamide compounds: For applications requiring high impact resistance, polyamides are modified with impact modifiers. These compounds are used in the production of sports equipment and automotive components.

Wear-resistant polyamide compounds: For applications requiring high friction and wear resistance, polyamides are modified with additives such as graphite, PTFE, or molybdenum disulfide.

Parsa Polymer Sharif's Polyamide Compounds

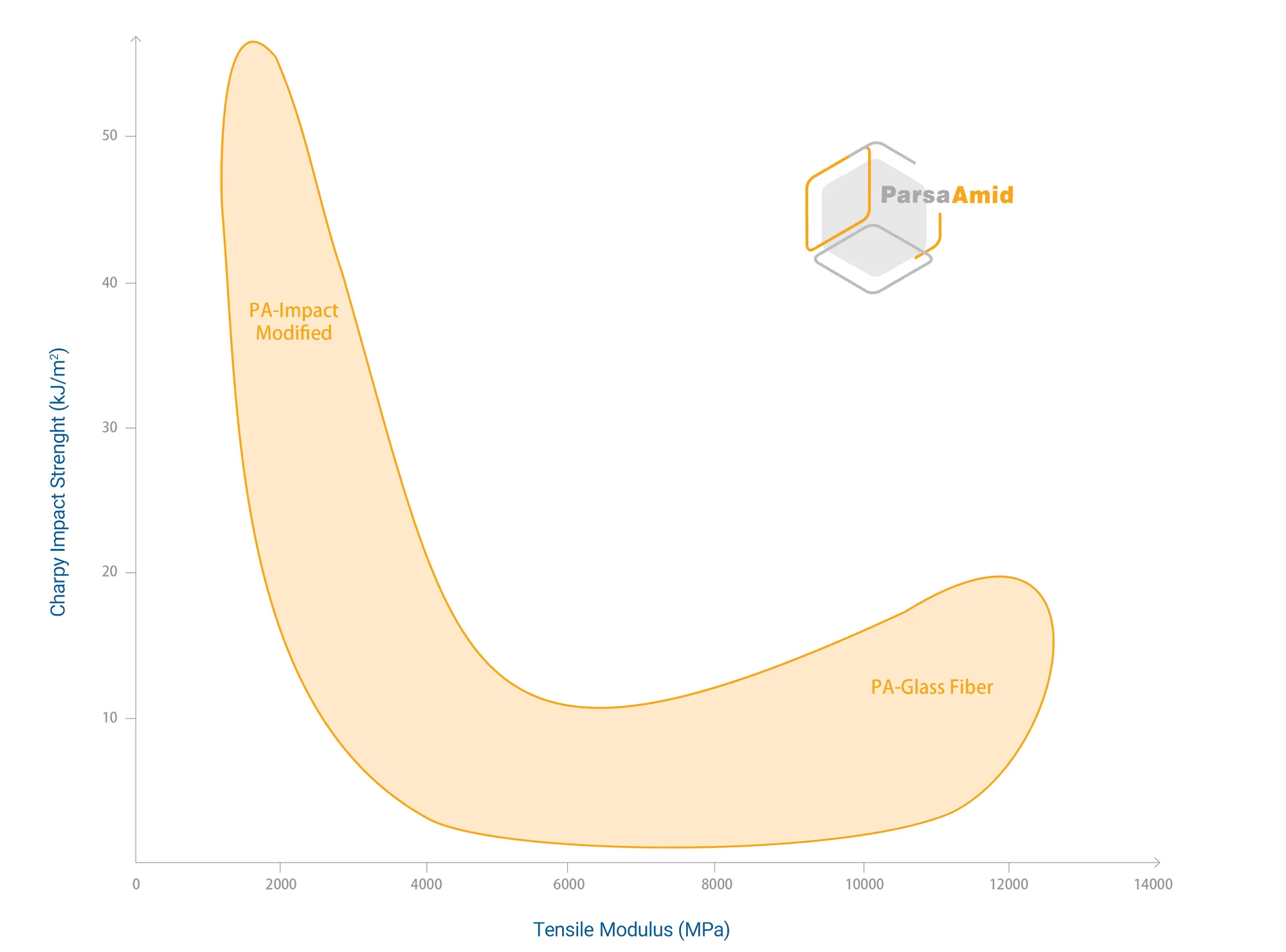

Parsa Polymer Sharif produces polyamide compounds based on PA6, PA66, and PA6/PA66 blends under the brand name ParsaAmid. These compounds, designed with a competitive price and a wide range of mechanical properties (Figure 1), are used in various industries, including automotive, electrical and electronics, and consumer goods. Parsa Polymer Sharif’s products can be processed using different methods such as injection molding and extrusion.

Figure 1 - Changes in tensile modulus and impact strength of Parsa Polymer Sharif’s polyamide compounds.

Parsa Polymer Sharif offers various polyamide compounds, including glass fiber reinforced, mineral filled, impact modified, flame retardant, heat resistant, wear resistant, and UV resistant grades. The company also offers environmentally friendly polyamide compounds containing recycled content to meet the demands of green and sustainable markets.

References

- https://www.rtprototype.com/what-is-polyamide/

- https://europlas.com.vn/en-US/blog-1/exploring-the-versatile-world-of-polyamide-properties-uses-and-beyond

- https://www.ensingerplastics.com/en/thermoplastic-materials/pa-polyamide